Quality Greek olive oil

Our accumulated experience together with our knowledge and direct contact with the product is our main advantage over big businesses.

Integrated management from harvest to selection of the best quality olive oil and its final standardization is our strength.

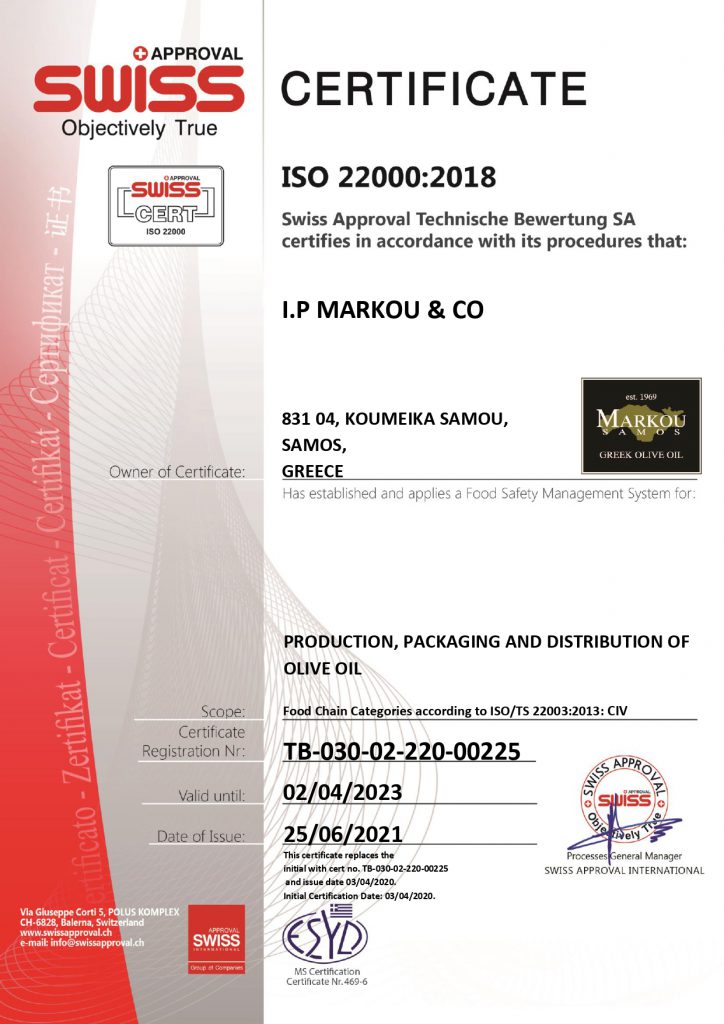

Our company strictly applies the requirements of ISO 22000: 2005 Food Safety Management System.

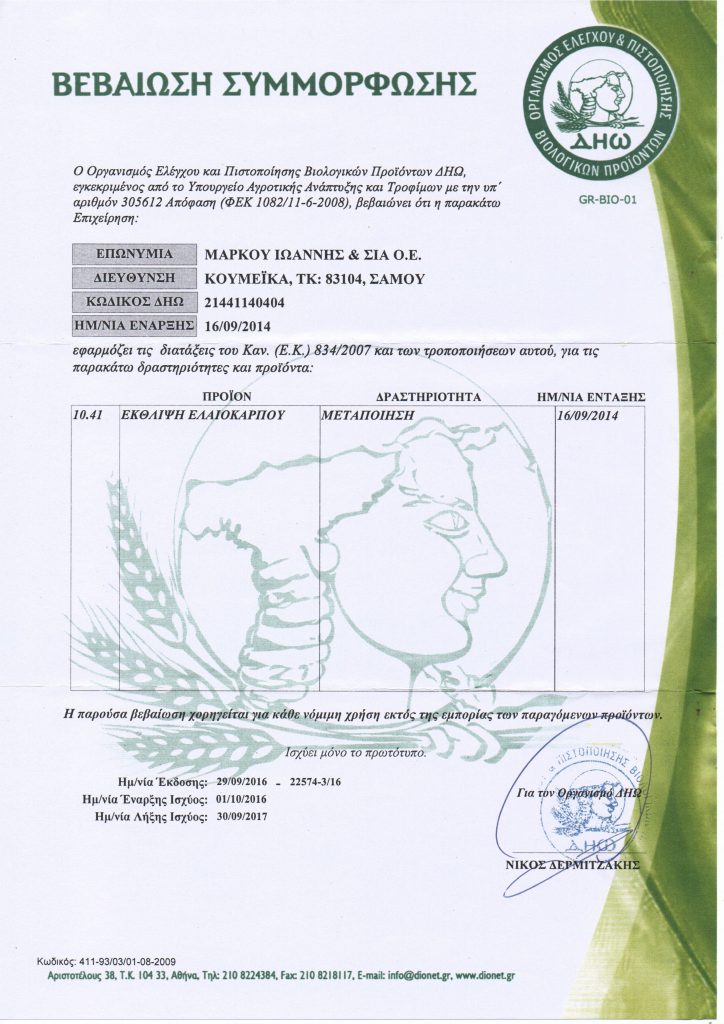

In addition, we have been certified by the Inspection and Certification for Organic products Organization ΔΗΩ and the Greek State, having been placed in controlled standardization system with certification code EL 40-128.

Our Company is prossesses all the credentials for P.D.O. & P.G.I. products. From 2016, has been found to conform to the standards of packaging and trading of << SAMOS P.G.I >> Olive oil.

Protected Geographical Indication (PGI) is the european recognition for an agricultural product of food, produced and processed in a specific geographic area.

<< SAMOS P.G.I. >> Olive Oil is a product that comes only from ”Troumbolia”, a local variety of SAMOS Greece island.

Production Process

How we make the finest extra virgin olive oil

After harvest, olives are carried to the olive oil mill, where they undergo various stages of preparation before the process of olive oil extraction begins.

The first step in the olive oil extraction process is to pass the fruit through special olive cleaning machines to remove leaves, stems and twigs. This automatic procedure is essential because a large quantity of leaves, when are combined together with the olives, adds bitter taste and a lot of chlorophyll (green colour) to the oil, which prevents it from maintaining its quality.

Next comes the stage of washing the olives, where foreign matter contained (soil, dust) is removed while the automatic weighing of the clean fruit takes place at the same time.

The grinding (crushing) of the fruit – cutting it into tiny pieces – which forms the Olive paste is known as the important stage of “Ekthlipsis”.

Not many years ago the crushing of the fruit was done in stone mills using 3 or 4 stone wheels of different diameter. In recent years the crushing stage is done with metal toothed grinders inside a perforated drum.

In order to separate oil from the paste which comes out of the grinder, the paste must be homogenized and very well mixed to allow maximum olive oil extraction.

The mixer (malaxer) is a device which homogenizes the paste. It consists of a horizontal trough with double side walls through which warm water passes to regulate temperature. Inside the malaxer a number of blades rotate continuously and mix the paste. The malaxing temperature must not exceed 28 °C. The same applies to all stages of the process. This is why it is called cold extraction. Once malaxing is completed, the olive paste is ready for the stage of separating the solids from the juice in which olive oil is contained.

Today, the separation of the Olive Oil juice from the core is done with a centrifuge (Dekanter) which makes good use of the difference between the specific weight of the main components of the oil paste, i.e. solids, water and oil.

The machine separates and removes the dry core from the oil along with an amount of water.

For the final process, the mixture of juice and oil passes through another centrifuge.

The liquid coming from the first separator is carried through pipes to the next and most crucial stage of the process; that of the final separation of olive oil.

For that, we use other type centrifugal separators (vertical) for thorough separation of Olive oil from water.

When this procedure is completed, we classify and arrange the Olive oil in different stainless tanks depending on the first assessment we make on the organoleptic and chemical characteristics.